At FuelMaxx, we’re always researching, testing, and innovating—but at the end of the day, the only data that truly matters is how our FMD performs for our customers. Below, you’ll find sampling of reports we have created for a diverse group of customers. It is important to note that all testing and data collection were carried out by the customers’ internal teams, ensuring complete transparency and credibility.

REFERENCES AVAILABLE BY REQUEST

1. Introduction:

This report outlines the evaluation of emissions reduction and fuel consumption optimization achieved by installing a FMDfuel device i.e. FMD on diesel generator of marine maintenance company, UAE. The study includes a comparison of pre- and post-installation emissions measurements, gathered using the HPC501 gas analyser. Key emissions parameters measured were hydrocarbons (HC), carbon monoxide (CO), carbon dioxide (CO2), oxygen (O2), and nitrogen oxides (NOx). Based on the emissions data, the fuel consumption in litres per hour (LPH) is calculated for both the pre- and post-installation phases, demonstrating the FMD's impact on improving fuel efficiency.

2. Objective:

The primary objectives of this study are:

· To establish baseline emissions

· To estimate the average fuel consumption rate using an established empirical formula.

· To establish a reference point for evaluating the performance improvements after FMD installation.

3. Equipment Details:

Engine Make: KOMATSU

Engine Model: S6D108E-2

Engine Serial Number: 36897

Ref#: DG#1

Genset Capacity: 113 kW @ 1300 rpm, 132 kW @ 1800 rpm

4. Methodology:

4.1 Emissions Testing procedure:

Emissions testing was conducted from the exhaust tail pipe of the diesel genset under three engine speed conditions:

· Idle speed

· Medium speed

· Full speed

A calibrated HPC501 emissions analyser was used to measure the following parameters of emissions:

· CO2 (%)

· HC (ppm)

· NOx (ppm)

· CO (%)

· O2 (%)

4.2 Fuel Consumption Estimation:

Fuel consumption rate is estimated using the formula developed by Heseding and Daskalopoulos (2006) as given below:

LPH = 63.47*CO2 (vol%) * kW/fuel density (kg/m3)

Where:

LPH: Estimated fuel consumption rate (Ltr/Hour)

CO2: Average volume of measured CO2

kW: Rated capacity of genset

5. FMD Installation:

After recording the baseline emissions data, FMD was installed on DG#1 by the team of client on 14th Feb. 2025. The device works by breaking down complex hydrocarbons into simpler molecules, enhancing fuel-air mixture combustion and thus reducing harmful emissions.

6. Post-Installation Emissions Testing:

Post-Installation emissions testing was conducted after 250+ hours of engine operation with the FMD in place. Using the same HPC501 gas analyser, post-installation emissions data were recorded for comparison with the baseline results.

7. Baseline Parameters:

Project Particulars

Project Summary

Emissions Reduction Summary

GHG Accounting Summary

Executive Summary

Introduction

Project Setup

Objective

FUEL CONSUMPTION IMPROVEMENT AND GHG EMISSIONS REDUCTION REPORT

GOVERNMENT MINING COMPANY

8. Post Installation Parameters:

9. Comparative Analysis:

11. Conclusion:

The installation of the FMD fuel catalyst on the aforementioned engine resulted in a measurable reduction in fuel consumption and harmful emissions particularly CO2 levels. These findings demonstrate the effectiveness of the FMD technology in enhancing fuel combustion efficiency and reducing the fuel consumption and GHG impact of the engines.

Overall, the outlined objectives of lowering fuel consumption, GHG emissions & engine efficiency KPI’s were successfully achieved, contributing to both environmental and operational benefits.

TABLE OF CONTENTS

Methodology

Evaluation Metrics

Findings

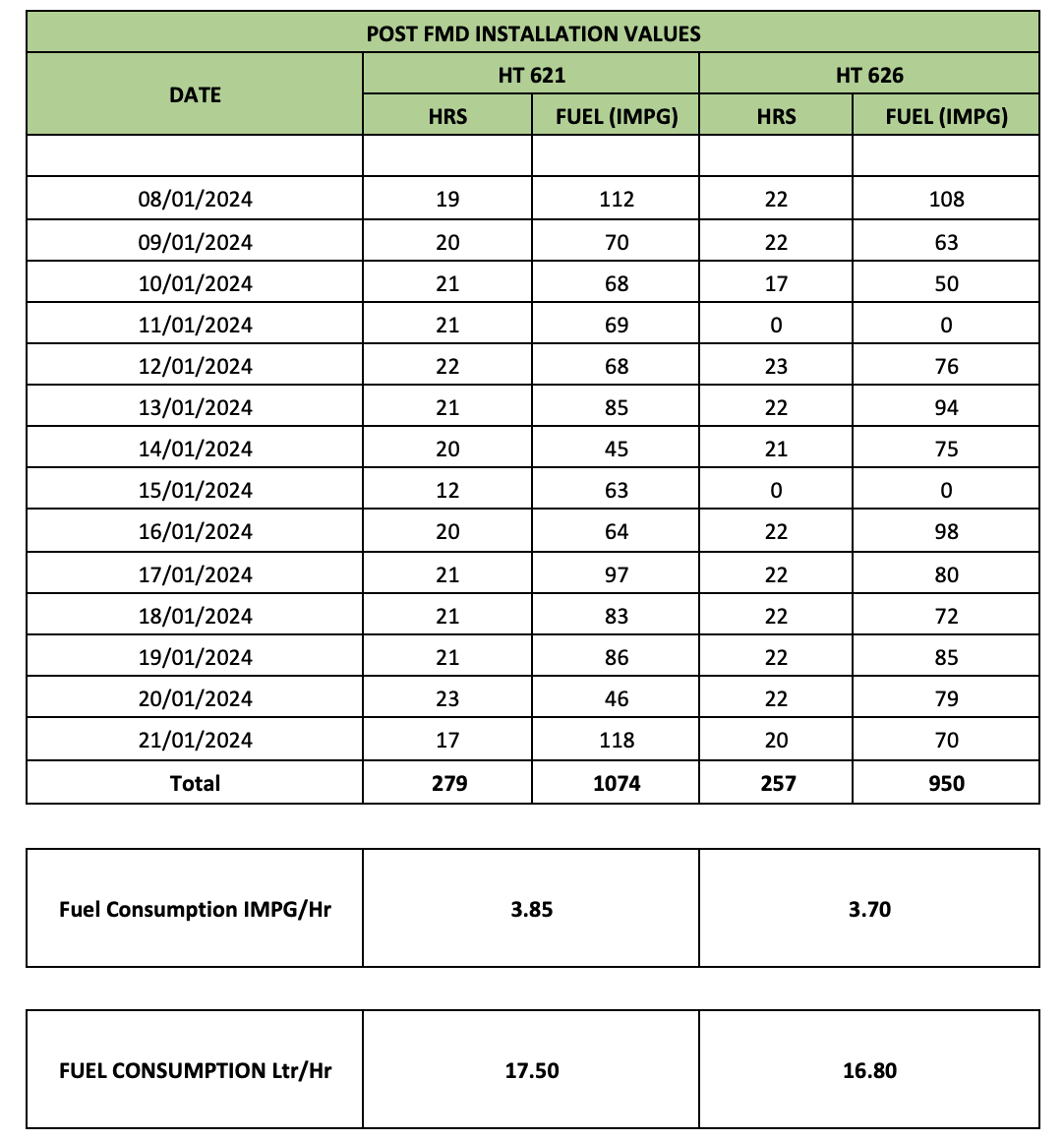

HT621/HT626

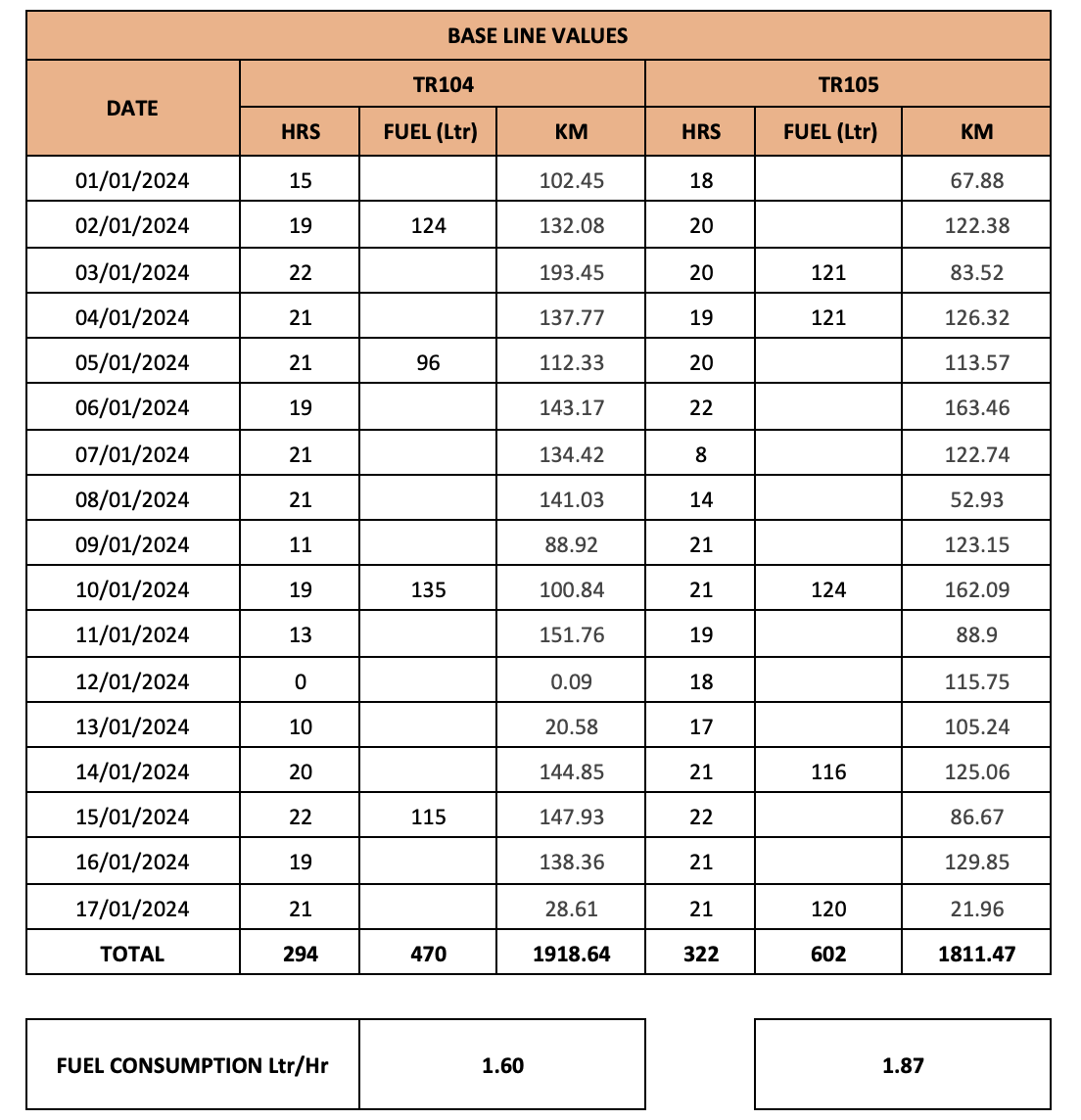

TR104/TR105

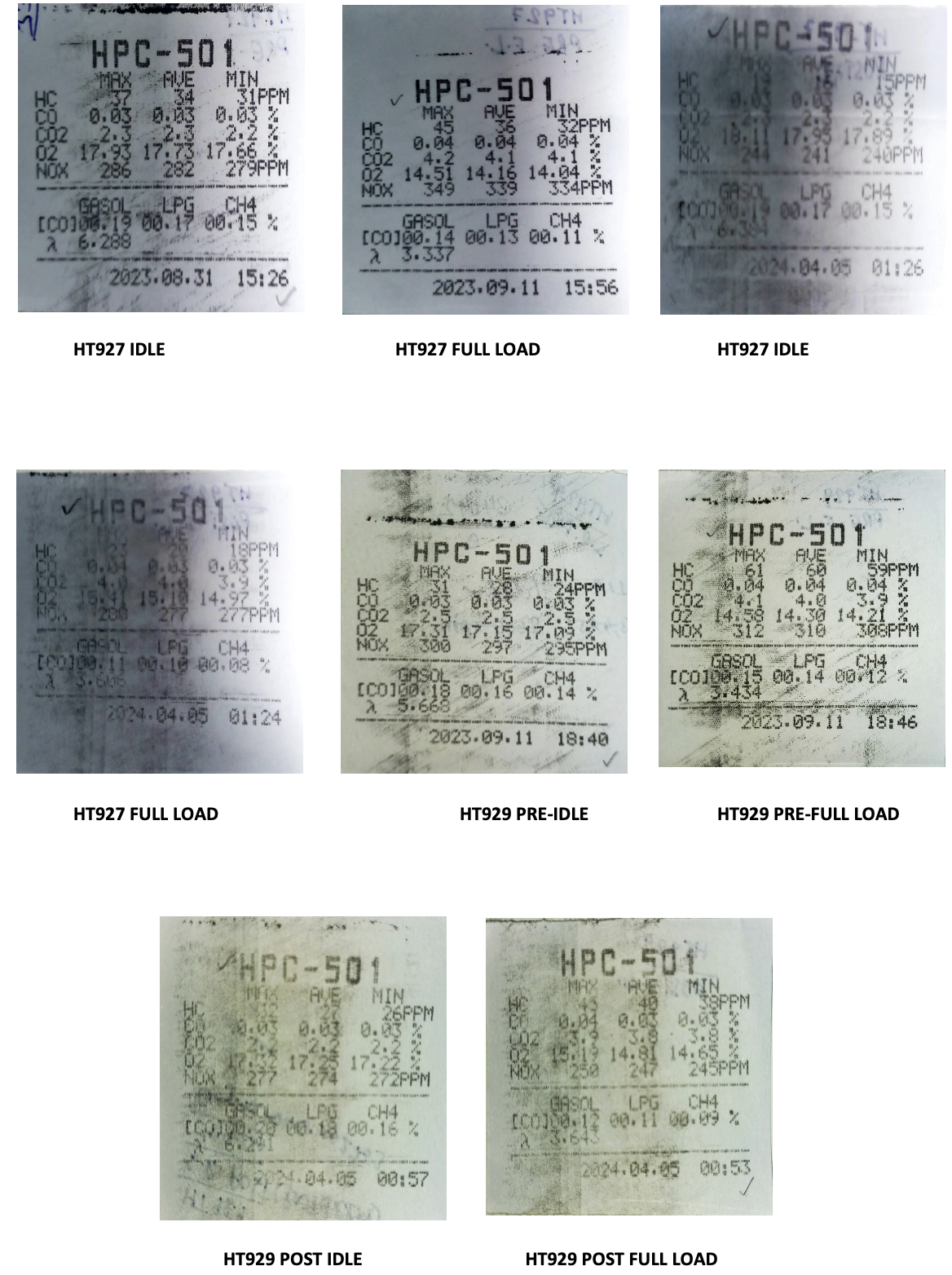

HT927/HT929

HT610/HT615

Conclusion

Recommendations

GHG Emissions Reduction Report

HT621/HT626

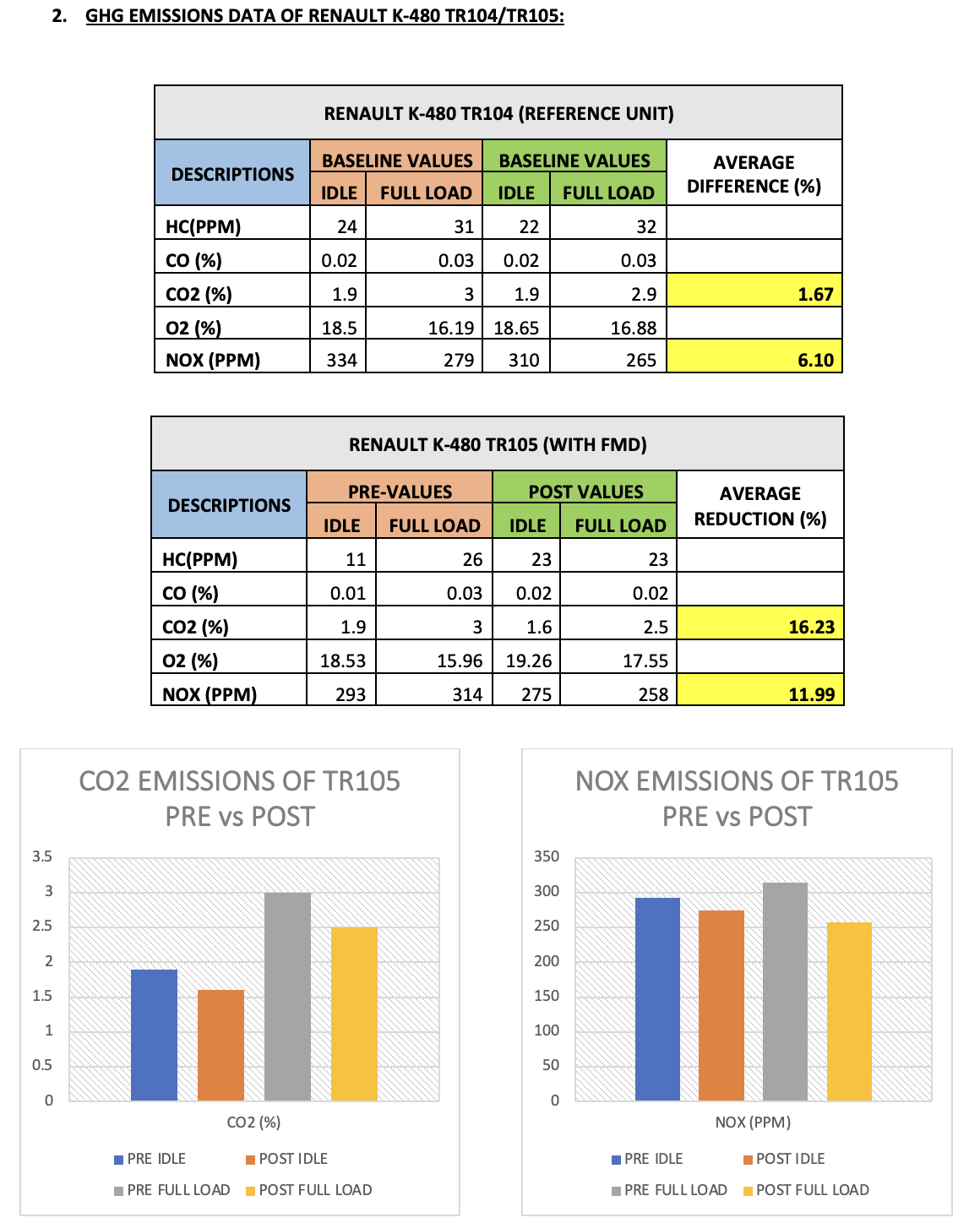

TR104/TR105

HT927/HT929

HT610/HT615

FMD Installation Images

Fuel Data

Note:

1. For GHG Accounting purpose we have considered the operating hours of each vehicle to be 18 hours per day.

2. The metrics provided above are on annual basis.

3. The GWP data is sourced from IFMD AR5

EXECUTIVE SUMMARY:

This technical report presents the findings of a pilot project conducted at Government mining company, uae to evaluate the effectiveness of FMD fuel generators in reducing fuel consumption and emissions in mining trucks. The project involved the installation of fuel generators in selected trucks, followed by a comprehensive analysis of fuel consumption and emissions data. Results indicate a significant reduction in both fuel consumption and emissions post-installation, highlighting the potential benefits of FMD fuel generator usage in mining operations.

INTRODUCTION:

A pilot project was initiated to assess the impact of fuel generator on fuel efficiency and emissions in mining trucks. The project aimed to address environmental concerns while improving operational efficiency. Two trucks of each model were selected for the study with one serving as a control unit and other as a master unit for FMD installation.

This report outlines the execution and analysis of FMD fuel generator project conducted on four sets of mining trucks operated by Government mining company, based in Ras Al Khaimah, UAE. The primary objective was to assess the impact of FMD on fuel efficiency and emissions reduction in the context of mining truck operations.

PROJECT SETUP:

Four sets of mining trucks were selected for this project. In each set, one truck served as the control unit while the other was outfitted with the FMD and designated as master unit. We relied on the client’s fuel fill and running hours data to establish baseline and post installation metrics.

OBJECTIVE:

The primary objective of the pilot project is to assess the impact of fuel generators on fuel consumption and emissions in Government mining company's equipment fleet. Specifically, the project aims to:

· Measure baseline fuel consumption and emissions data.

· Install fuel generators on selected equipment.

· Monitor fuel consumption and emissions post-installation.

· Analyse the data to determine the effectiveness of the fuel generators in reducing fuel consumption and emissions.

METHODOLOGY:

1. Baseline Data Collection:

· Prior to the installation of fuel generators, 250 hours of fuel consumption data were collected from the customer's records to establish a baseline.

· Pre-installation emissions were also assessed using an HPC501 gas analyser.

2. Fuel generator Installation:

· Fuel generators were installed on the selected equipment according to standard guidelines.

3. Clean-up Period

· A clean-up period of 250 hours was observed post-installation to allow the devices to optimize performance.

4. Post Installation data collection

· Fuel consumption and engine running hours data were collected from the Client’s own record for the subsequent 250 hours after the clean-up period.

· Post-installation emissions were assessed using the HPC501 gas analyser.

5. Data Analysis

· Baseline and post-installation data were analysed to determine the reduction in fuel consumption and emissions.

EVALUATION METRICS:

Fuel efficiency improvements were measured in litres per hour, comparing the performance of trucks with and without the FMD. Additionally, we conducted exhaust emissions testing using an HPC501 gas analyser before and after FMD installation to assess changes in emissions levels.

FINDINGS:

CONCLUSION:

The pilot project confirmed the effectiveness of FMD fuel generators in reducing fuel consumption and emissions in mining trucks. Installation of fuel generators led to significant improvements in operational efficiency and environmental performance. These findings underscore the potential benefits of widespread adoption of fuel generator technology in mining operations.

RECOMMENDATIONS:

Based on the positive outcomes of the pilot project, it is recommended to consider implementing FMD fuel generators across the mining truck fleet at Government mining company.

GHG EMISSIONS REDUCTION REPORT

1. Introduction:

This report documents the fuel-saving benefits achieved by integrating the FMD on two key engines aboard the BARGE; Main Engine - 1 (propulsion) and Auxiliary Engine - 3 (power generation). By comparing pre- and post-installation data over significant operating periods, the analysis confirms improvements in Specific Fuel Consumption (SFC) i.e. Ltr/kWh and overall combustion efficiency.

2. Objective:

To evaluate the fuel-saving potential of the FMD device under real-world marine operating conditions by monitoring and comparing engine performance before and after FMD integration.

3. Equipment Details:

MAIN ENGINE - 1

a. Make: HIMSEN

b. Rated Output: 1600 KW @ 900 rpm

c. Cylinder configuration: In – line

d. Operation: To operate propeller

AUXILIARY ENGINE - 3

a. Make/Model: CUMMINS/QSM11-DM

b. Rated Output: 317 KW @ 1800 rpm

c. Cylinder configuration: In- Line

d. Operation: Auxiliary Engine

4. Data Collection Methodology:

A. Main Engine - 1:

During both BOSP and EOSP operations, the following parameters were systematically recorded and maintained by the engineering staff onboard the barge:

i) Fuel Consumption (Ltr): Measured using the fuel flow meter installed by CLIENT

ii) Engine Operating hours: Captured via CLIENT’s onboard meter

iii) kWh Output: Monitored using the onboard meter installed by CLIENT

B. Auxiliary Engine – 3:

For Auxiliary Engine 3, the same parameters were monitored and recorded by the BARGE staff during BOSP and EOSP operations with instrumentation as follows:

i) Fuel Consumption in Ltr: Measured using the fuel flow meter installed by CLIENT

ii) Engine Operating hours: Captured via CLIENT’s onboard meter

iii) kWh Output: Logged via the electrical data logger installed by Ai360LLC

5. Calculation Methodology:

Specific Fuel Consumption (SFC) was used as the key performance indicator for energy efficiency, calculated as:

SFC (L/kWh) = Total Fuel Consumed (Litres) / Total Energy Output (kWh)

6. FMD Installation:

FMD FUEL SAVING REPORT

MARINE ENGINE

7. Results Summary:

8. Conclusion:

The results clearly demonstrate that the FMD improves fuel efficiency across both main and auxiliary engine applications:

· Main Engine -1: 33% fuel efficiency gain

· Auxiliary Engine – 3: 8.33% fuel efficiency gain

9. Recommendations:

· Consider FMD deployment on remaining engines aboard the vessel for cumulative savings.

· Evaluate potential integration across other vessels in the fleet to replicate benefits.

FORTUNE 500 OIL & GAS COMPANY

FMD FINAL REPORT

Introduction:

This report outlines the evaluation of emissions reduction and fuel consumption optimization achieved by installing a FMDfuel device i.e. FMD on four diesel engines of FRAC FLEET at Fortune 500 Oil & Gas Company, Oman. The study includes a comparison of pre- and post-installation emissions measurements, gathered using the HPC501 gas analyser. Key emissions parameters measured were hydrocarbons (HC), carbon monoxide (CO), carbon dioxide (CO2), oxygen (O2), and nitrogen oxides (NOx). Based on the emissions data, the fuel consumption in litres per hour (LPH) is calculated for both the pre- and post-installation phases, demonstrating the FMD's impact on improving fuel efficiency.

Pre-Installation Emissions Testing:

Initial emissions testing was conducted on each engine using the HPC501 gas analyser to establish baseline emissions values.

FMD Installation:

After recording the baseline emissions data, FMD was installed on each of the four engines. The device works by breaking down complex hydrocarbons into simpler molecules, enhancing fuel-air mixture combustion and thus reducing harmful emissions.

Post-Installation Emissions Testing:

Post-Installation emissions testing was conducted after 250+ hours of engine operation with the FMD in place. Using the same HPC501 gas analyser, post-installation emissions data were recorded for comparison with the baseline results.

· *The fuel Consumption rate before and after the installation of FMD fuel device has been estimated from on-field emissions test data.

· The formula to calculate fuel consumption is derived from European Standard and developed by Heseding and Daskalopoulos, 2006 (LPH = 63.47*CO2 (vol%) *kw/fuel density (kg/m3)

Reliability:

· Combined engine hours of approximately 2000+ (all 4 test engines)

· No performance related issues observed or reported

· Units performed as per factory design

Conclusion:

The installation of the FMD fuel device on the aforementioned engines resulted in a measurable reduction in fuel consumption and harmful emissions particularly CO2 and NOx levels. These findings demonstrate the effectiveness of the FMD technology in enhancing fuel combustion efficiency and reducing the fuel consumption and GHG impact of the engines.

Overall, the outlined objectives of lowering fuel consumption, GHG emissions & engine efficiency KPI’s were successfully achieved, contributing to both environmental and operational benefits.

FUEL CONSUMPTION IMPROVEMENT REPORT

MARINE ENGINE – OIL & GAS

FMD (POC)

INTRODUCTION:

The primary objective of this report is to conduct a meticulous evaluation of the fuel consumption improvement post FMD device installation in terms of Litres per Kilowatt-Hour (L/KWH), for the marine diesel generator sets (DG#4).

PUPROSE OF THE FMD FUEL DEVICE (FMD):

The primary objective of FMD is to improve fuel economy and reduce harmful emissions of internal combustion engines. By employing advanced molecular modifications, this cutting-edge technology aims to optimize the combustion process resulting in superior engine performance and reduced environmental impact.

FMD FUNCTIONALITY:

The FMD employs a proprietary device composition designed to interact with fuel molecules during combustion process. This seamlessly integrated device is typically installed within the fuel line where it can treat the fuel before it enters the combustion chamber. The FMD facilitates the de-clustering of fuel molecules promoting a more complete and efficient combustion process.

BENEFITS OF THE FMD:

The FMD offers a multitude of potential benefits that can revolutionize the efficiency and sustainability of internal combustion engines:

a) Enhanced Fuel Economy: By enhancing the combustion process the FMD substantially improves overall fuel efficiency resulting in reduced fuel consumption and significant cost savings.

b) Emission Reduction: Through optimized combustion process the FMD reduces the GHG emissions such as CO, NOx, and particulate matter (PM).

c) Augmented Engine Performance: The FMD’s unique combination of metals and rare earth elements contributes to enhanced engine performance including increased power output, smoother operation and reduced engine deposits. These improvements result in overall engine performance and extended engine longevity.

d) Less Downtime/Maintenance: The FMD device helps to improve engine performance which can reduce the frequency of maintenance and repairs required. This in turn can lead to less downtime as the engine will be able to operate for a longer period without the needs for maintenance or repairs.

EQUIPMENT DETAILS:

FMD DEVICE INSTALLATION:

The FMD device was installed on 30th November 2023 on DG#4 for the improvement of fuel consumptions.

FUEL CONSUMPTION DATA COLLECTION AND ANALYSIS (PRE & POST DATA):

The OEM provided fuel consumption data is recalculated to find out the specific fuel consumption (SFC) of the aforementioned DG sets in terms of Litres/KWH.

The recalculated data in terms of Litres/KWH underwent a comprehensive analysis, enabling a nuanced examination of fuel consumption trends. Special emphasis is placed on the recalculated Fuel Consumption SFC to derive insights into the efficiency of DG sets.